In oil, gas and energy every action counts. The consequences of errors and inconsistencies are immediate and can impact safety, downtime, adherence to regulations and reputation.

Work must be completed correctly, efficiently and fully compliant — every time.

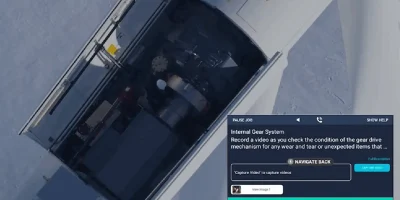

WorkfloPlus replaces paper checklists and disconnected reporting with structured digital work instructions and real-time evidence capture. Personnel are guided step-by-step through inspections, maintenance and operational tasks, while verifiable proof is captured automatically.

You know what was done, who did it and how it was completed – in real-time.

Energy operations are complex. Work is often performed in hazardous, remote or high-pressure environments where the margin for error is small.

Paper-based systems create gaps:

WorkfloPlus ensures critical procedures are followed consistently. Mandatory checkpoints are validated. Photos, measurements and confirmations are captured at the point of work.

Instead of chasing paperwork, you gain reliable, attributable records in real time.

WorkfloPlus can be deployed on voice-controlled smart glasses such as the intrinsically safe RealWear Navigator Z1, enabling engineers to follow procedures and capture confirmations hands-free.

Tasks are completed safely, evidence is recorded in real time and reports are no longer extra admin at the end of the job.

In drilling and upstream environments, procedural adherence is critical.

WorkfloPlus guides operators through inspections, equipment checks and safety confirmations with structured digital instructions that reduce risk and capture defensible evidence in real time.

Pipeline inspections, pressure system checks and valve maintenance require accurate execution and traceable documentation.

WorkfloPlus standardises these tasks, enforcing mandatory confirmations and capturing structured evidence that supports reliability and compliance.

Refineries and processing plants operate under strict operational and regulatory standards.

WorkfloPlus ensures maintenance, safety checks and operational procedures are followed correctly and documented with full traceability, reducing compliance risk.

Remote and distributed teams require clear guidance and instant reporting tools.

WorkfloPlus delivers structured digital instructions on mobile and wearable devices, capturing confirmations and evidence even in challenging field conditions.

Embed safety into every task

Hazard assessments and safety confirmations are completed and recorded as part of normal work.

Evidence is captured in real time, reducing reliance on paper forms and improving accountability.

Standardise work across assets

Preventive and corrective maintenance activities are guided step-by-step, ensuring tasks are completed fully and recorded accurately.

This improves reliability and reduces unplanned downtime.

Control complex procedures

Turnarounds involve multiple teams, assets and high-risk tasks.

WorkfloPlus provides consistent guidance with evidence capture, ensuring work is controlled, compliant and fully traceable.

Know exactly what happened

Every task creates a secure, time-stamped record showing who performed the work, which procedure was followed and what evidence was captured.

Accountability is built into every procedure.

Record issues in context

When unexpected conditions arise, deviations are recorded directly within the task.

Supporting photos, measurements and notes are captured immediately, reducing ambiguity and accelerating corrective action.

Everyday audit proof execution

Whether operating to ISO standards, environmental regulations or internal governance, WorkfloPlus creates evidence as work is performed.

Your compliance trail is built through normal operations — not recreated later.

Capture best practice

New personnel are guided with digital work instructions that embed best practice from your most experienced workers.

This speeds up onboarding, ensures safety and improves confidence and efficiency across teams.

Capture data other systems miss

WorkfloPlus records task execution data directly from frontline activity.

You gain visibility into how work is performed across assets and sites, creating a foundation for continuous improvement and AI-ready analytics.

Planning systems schedule work.

CMMS tracks tasks.

Safety systems define standards.

But none of them guarantee how work was actually performed.

WorkfloPlus works alongside your existing systems, strengthening the final step — where work is executed and evidence is captured.

If you want safer operations, stronger compliance and clearer visibility across oil, gas and energy operations, we can help.

Book a tailored demonstration to see how WorkfloPlus supports Oil, Gas & Energy operations.

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.