WorkfloPlus for Machinery & Equipment Manufacturers

Digital Work Instructions to Ensure Precision, Quality & Consistency

Machinery and equipment manufacturers deliver complex products with tight tolerances. Every installation, inspection and build process needs to be performed correctly, consistently and with clear evidence.

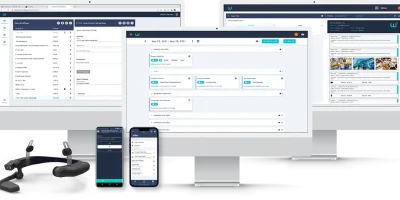

WorkfloPlus replaces paper forms and disconnected processes with guided digital work instructions and real-time evidence capture.

Operators, engineers and service teams are guided step-by-step through critical tasks, while proof of work is captured automatically. To create complete, accurate records without extra admin.

The result is simpler processes, higher quality and full traceability across the entire product lifecycle.

Turning Complex Procedures Into Repeatable Processes

For machinery and equipment manufacturers, success depends on carrying out detailed work correctly and efficiently, every time.

Whether it’s assembling precision components, carrying out factory acceptance testing, installing equipment on a customer site or performing routine maintenance, small errors can lead to big problems.

Traditional paper-based methods make this harder than it needs to be. Instructions become out of date. Steps are skipped. Evidence is incomplete. And valuable know-how stays locked in the heads of experienced staff.

WorkfloPlus changes that.

Your approved procedures become interactive digital work instructions that guide teams through each job in a clear, structured way. Validations and mandatory fields ensure critical steps are never missed, while photos, measurements and signatures create a permanent record of what was done.

Instead of relying on memory and paperwork, you get a consistent, controlled way of working that scales across employees, sites and customers.

One Platform Across the Product Lifecycle

Machinery and equipment suppliers don’t just manufacture products – they install them, commission them and support them in the field.

WorkfloPlus supports that entire lifecycle.

From the factory floor to customer sites, digital work instructions can be used to standardise assembly, testing, delivery, installation and ongoing service. Every stage produces structured job execution data, giving you visibility far beyond what existing systems can provide.

Quality teams gain reliable evidence. Service managers get accurate job reports. And managers gain real insight into how work is actually being performed.

Real Evidence, Not Just Reports

For many manufacturers, proving what has been done is just as important as doing it.

WorkfloPlus captures evidence directly at the point of work. Each completed task creates a secure, time-stamped record showing who performed the job, which procedure was followed and what results were recorded.

That means faster customer sign-off, clearer handover documentation, fewer disputes and quicker payments, whether you’re dealing with internal quality requirements, ISO standards or customer audits.

Designed for Frontline Teams

WorkfloPlus has been developed to be used by the people doing the actual work.

Digital work instructions are accessible on mobile devices, tablets, desktops and smart glasses, so engineers and operators can follow guidance hands-free if needed, wherever the job takes them.

There’s no need for complex IT projects or specialist coding. Processes can be created, updated and deployed quickly, keeping instructions aligned with real operational needs.

Built for Every Stage of Machinery & Equipment Operations

Assembly and Production

Get every build right first time

WorkfloPlus guides engineers through detailed assembly procedures step-by-step, ensuring components are fitted correctly and in the right sequence. Measurements, checks and confirmations are captured in real time, creating a complete digital record for every unit produced. Quality becomes repeatable, not dependent on individual experience.Factory Acceptance Testing

Standardise testing and prove results

Testing and verification procedures are carried out using structured digital work instructions that ensure nothing is missed. Results are captured consistently, with photos and data logged automatically. Every machine leaves the factory with a clear, auditable history.Installation and Commissioning

Deliver consistent performance on customer sites

When equipment is installed in the field, WorkfloPlus ensures engineers follow the correct procedures, capture site-specific evidence and produce professional digital reports instantly. Handover documentation becomes faster, clearer and more reliable.Total Traceability

Track every task, part and action

WorkfloPlus links people, processes and evidence into a single digital trail. You can see exactly what was done, who did it and when – whether the work happened in your factory or on a customer site. No missing paperwork, no uncertainty, just complete visibility.Quality and Compliance

Meet standards without creating more admin

Quality checks, inspections and certifications become part of everyday work rather than separate paperwork exercises. Each completed step builds a clear audit trail for ISO and customer requirements, helping you demonstrate compliance with confidence.Knowledge Capture

Protect the expertise your business relies on

Your most experienced engineers know the best way to perform complex tasks. WorkfloPlus captures that knowledge digitally and turns it into repeatable, guided processes. When people move on, their know-how stays in the business.Field Service and Maintenance

Support customers with accurate, reliable service records

Service teams use the same digital work instructions to carry out maintenance, repairs and inspections in the field. Every visit generates a structured report, improving customer confidence and giving you better visibility of asset performance.Training and Onboarding

Help new starters perform like experts

Instead of learning through trial and error, new employees follow guided instructions that show them exactly what to do. Training happens on the job, safely and consistently, reducing onboarding time and protecting quality.Real-Time Operational Insight

Capture the data other systems never see

WorkfloPlus records what really happens on the shop floor and in the field – directly from the people doing the work. You gain accurate information about cycle times, quality issues and process bottlenecks, helping you improve productivity and make better decisions.A Practical Path to Better Operations

Digital transformation doesn’t need to be complicated.

Most machinery manufacturers start with a single process – perhaps a critical assembly procedure or installation checklist – and expand from there. WorkfloPlus is quick to deploy, easy to update and flexible enough to grow with your business.

You don’t need to replace existing systems. WorkfloPlus simply strengthens the final step: ensuring work is performed correctly and captured properly.

From Paper Processes to Connected Operations

WorkfloPlus helps machinery and equipment manufacturers:

- Standardise complex procedures

- Reduce errors and rework

- Capture real evidence from the frontline

- Improve customer handovers

- Protect critical knowledge

- Gain visibility across production and service

If you’re looking to improve quality, increase efficiency and bring more control to your operations, we can help.

Contact us to see how WorkfloPlus supports machinery and equipment manufacturers.

Trusted by