An Inspection Test Plan (ITP) define when and what inspections and tests must take place during a process. They include what needs to be checked, and who is responsible for approving each stage. ITPs are commonly used in manufacturing and engineering, construction, utilities, and infrastructure projects, They ensure quality, safety, and compliance requirements are met consistently.

An ITP typically includes inspection stages, acceptance criteria, reference standards, and defined hold points or witness points. Hold points require work to stop until approval is given, while witness points allow an inspection to be observed without stopping progress. This structure ensures that critical checks are not missed and that quality is built into the process rather than inspected at the end.

Traditionally, ITPs are managed using spreadsheets, PDFs, or paper-based sign-off sheets. These methods often lead to delays, incomplete records, and poor visibility. Evidence may be captured separately, approvals may be unclear, and audit preparation becomes time-consuming. As a result, organisations struggle to prove compliance quickly or identify issues early.

Digitising ITPs improves accuracy, reduces rework, and gains real-time visibility of inspection status across projects and sites.

How this applies to WorkfloPlus

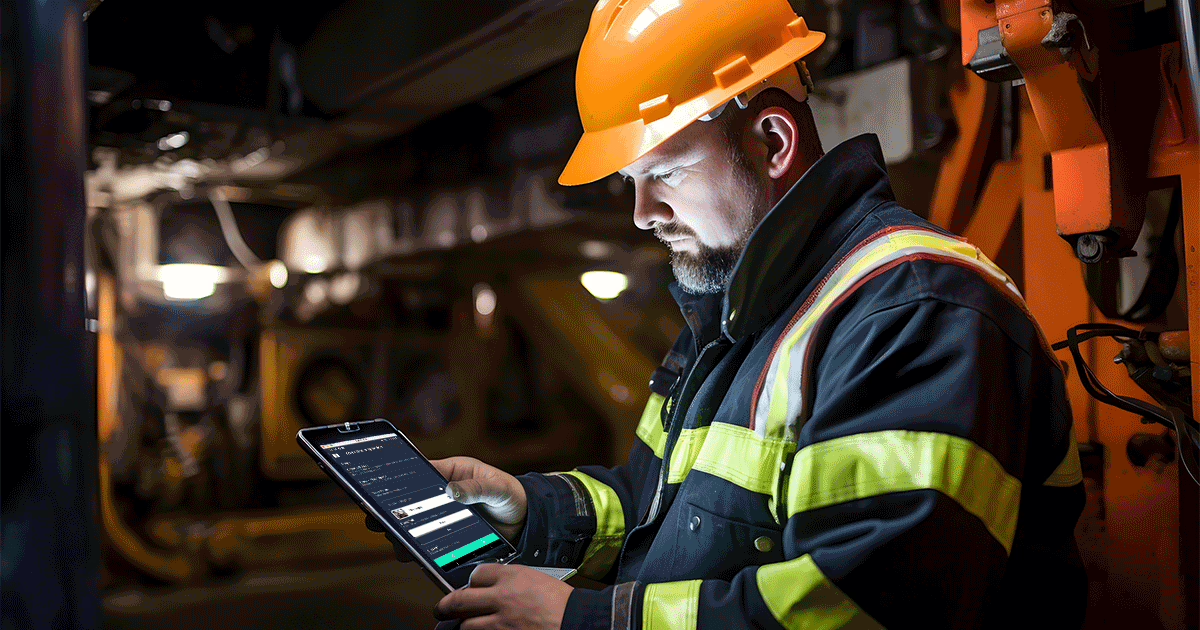

WorkfloPlus enables digital Inspection Test Plans by turning each inspection stage into a guided digital procedure. Mandatory checks, hold points, and approvals are built directly into the process. Inspectors capture photos, notes, measurements, and digital signatures at the point of work, creating a complete and time-stamped audit trail. Managers gain instant visibility of progress, approvals, and exceptions, making quality control faster, clearer, and more reliable.