WorkfloPlus gives you instant data, streamlined operations, and actionable insights.

You can help your teams work safely and confidently while keeping the network running smoothly and reliably.

Rail operations are complex, highly regulated, and spread across large networks. You need your teams to work safely, consistently, and with confidence while you gain real-time insights to make fast, informed decisions.

WorkfloPlus helps your teams spot hazards, follow safety standards, and respond quickly to problems. At the same time, you get reliable, auditable data and consistent operations across every site. This reduces errors, improves maintenance, and ensures your network runs efficiently.

By capturing operational knowledge digitally, WorkfloPlus also helps you close skills gaps, so your teams can work safely, efficiently, and confidently, even as experienced engineers retire or new staff join.

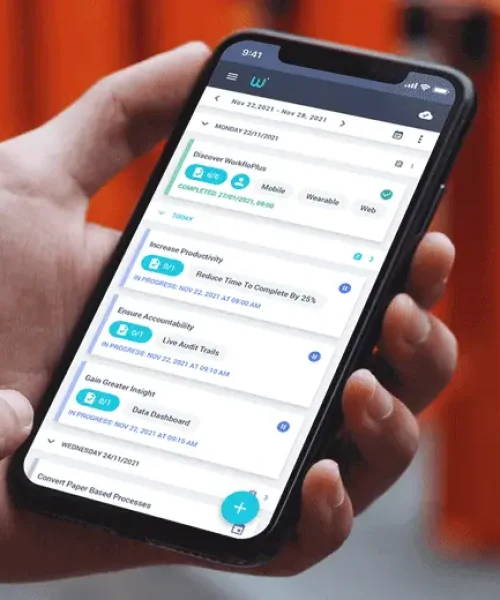

With WorkfloPlus, safety checks, inspections, and maintenance are logged automatically. This means you always have a clear, reliable record. You don’t have to chase paperwork or worry about missing steps.

By embedding compliance into everyday work, you protect your people, prevent accidents, and feel confident during audits. Safety and regulation become part of how you work, not a separate task.

Manual processes and paper forms often cause delays, miscommunication, and errors. WorkfloPlus gives your teams clear digital SOPs to follow every step of the way, ensuring tasks are completed correctly the first time.

This means your frontline teams feel confident, mistakes are reduced, and you can trust that operations consistently meet safety and performance standards across the network.

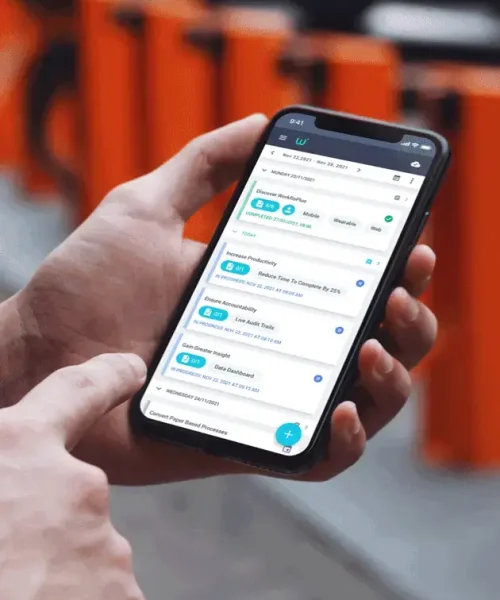

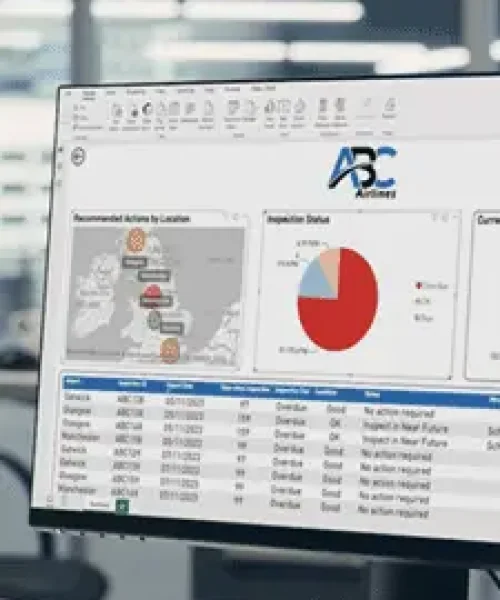

Delays in reporting create blind spots that risk downtime and safety. With WorkfloPlus, your teams capture data instantly on mobile devices, giving you a real-time view of maintenance, asset health, and network performance.

This allows you to prioritise work, respond quickly to issues, and prevent small problems from escalating, keeping trains running safely and on schedule.

Inefficient coordination can slow the entire rail system. WorkfloPlus streamlines inspections, maintenance, and repairs, making it easier for your teams to work together across locations.

You can maintain tight schedules, optimise resources, and ensure passengers and freight reach their destinations on time without disruption.

Waiting for expert assistance costs time and money. WorkfloPlus lets your teams connect in real time via live video, photos, or voice notes.

This ensures issues are diagnosed and resolved quickly, unnecessary site visits are avoided, operations remain safe, and you have peace of mind that every incident is handled efficiently.

When experienced engineers leave, their expertise can be lost. WorkfloPlus captures critical procedures digitally, allowing new or less-experienced teams to work safely and confidently.

This speeds up onboarding, protects organisational knowledge, and gives you confidence that every task is performed correctly, no matter who is on the team.

Reactive maintenance causes delays, extra costs, and safety risks. WorkfloPlus integrates with CMMS and asset management systems to provide predictive insights on equipment health.

By planning maintenance before issues occur, you can optimise resources, prevent unplanned downtime, and ensure your rail network runs reliably and efficiently.

Rail infrastructure is evolving fast. WorkfloPlus captures structured field data that can feed AI insights, predictive analytics, and strategic decision-making.

This lets your teams work efficiently today while preparing for automation, sustainability, and smarter infrastructure planning. You can stay ahead in a complex, competitive sector while continuously improving operations.

Intoware’s customer success model ensures your project achieves it’s goals, and provides ROI as quickly as possible.

On our Discovery call, we’ll find out about you and your existing processes to learn exactly what you’re looking for.

Configure your workflows. Customise templates with our toolkit or build processes from scratch.

Integrate your digital workflows with existing devices. We’re on hand to help with training, support and integration.

Stop worrying about visits from regulators and auditors. WorkfloPlus automatically builds rock-solid evidence trails for Health & Safety, ISO standards, and industry regulations. When inspectors ask "Can you demonstrate this was done properly?" At the click of a button you can!

Convert your paper-based SOPs, machine setups, and maintenance procedures into smart digital work instructions that are always current, always accessible. When procedures change, just make the update once and instantly roll-it out across all devices. End the hassle of outdated printouts and version confusion.

Transform routine inspections into early warning systems. Identify patterns in equipment deterioration, catch recurring problems, and demonstrate exactly when issues first appeared, and why. Turn your inspections into problem-prevention tasks that save your business money.

Don't lose decades of experience when workers leave. WorkfloPlus captures how your best performers actually do the job, then turns that knowledge into training that new starters can follow. See exactly where people struggle and build a library of proven methods to pass on to the next generation

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.