The Execution Layer

Closing the Gap Between Planning and Reality in Industrial Operations

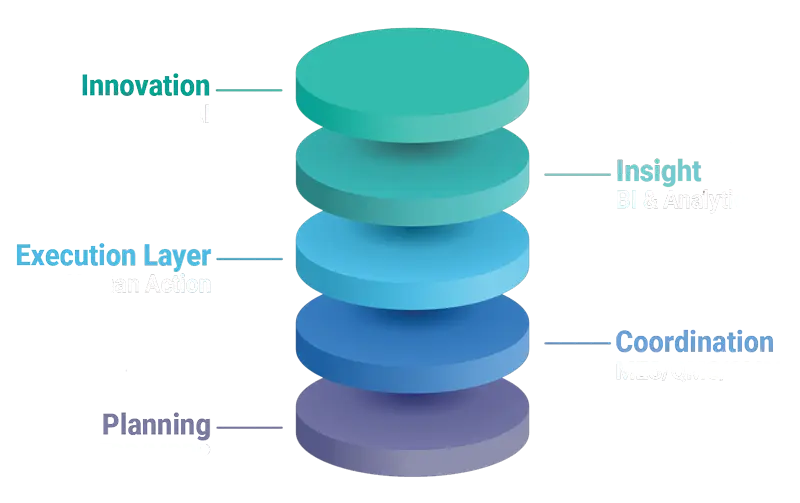

Every operation runs on two parallel worlds: the world of planning and the world of execution.

Planning lives inside ERP, MRP, MES, CMMS, QMS and scheduling systems.

Execution happens on shop floors, in the field, on the line, trackside, or on a job site.

And between these two worlds, there is a gap.

The plans say one thing.

Reality does another.

What is the Execution Layer?

The Execution Layer is the collection of human steps, checks, inspections, decisions and actions that determine the outcome of every job. It includes:

- how tasks are followed

- whether steps are missed

- the quality of evidence captured

- how consistently people work

- how long tasks take

- how confident teams feel

- whether standards are truly met

- Almost all of this is invisible in traditional systems.

Paper forms don’t capture it.

PDFs don’t enforce it.

Whiteboards don’t store it.

Memory isn’t measurable.

This is why so many operations “look fine in the system”, while frontline teams experience a very different reality.

Why the Execution Layer Matters More Now Than Ever

Across manufacturing, utilities, highways & construction, oil & gas, aviation MRO, and rail operations, managers face the same pressures:

- regulatory change

- workforce turnover

- the loss of experienced staff

- tight margins

- rising audit expectations

- increasing safety scrutiny

- the push for AI and automation

Yet most companies still rely on operational processes that were designed 20 years ago – paperwork, verbal guidance, PDFs, spreadsheets and tribal knowledge.

When execution is unstructured, everything else becomes unstable.

Variation creeps in.

Audits take too long.

Data is unreliable.

Reports don’t match reality.

AI initiatives stall due to poor frontline data.

Problems get discovered days or weeks after they occur.

A digital execution layer eliminates that uncertainty.

Digital Execution: How WorkfloPlus Closes the Gap

WorkfloPlus turns tasks into simple digital work instructions — followed on mobiles, tablets, desktops or smart glasses — while automatically capturing evidence.

As work is completed, the system automatically records:

- the steps followed

- photos and video

- timing and duration

- signatures

- location

- measurements

- compliance checks

- exceptions or issues

Suddenly, the job execution data becomes visible.

Not weeks later. Right now.

For frontline teams, it removes admin.

For managers, it removes guesswork.

For auditors, it provides evidence.

Free Download: Digital SOPs eBook

Learn how digital standard operating procedures eliminate variation and increase compliance.

How a Digital Execution Layer Changes Operations

- Real-time visibility: Work is no longer a black box. You see the real situation as it unfolds.

- Consistency across teams and sites: When everyone follows the same digital steps, variation drops naturally.

- Better evidence, automatically captured: Photos, timestamps, signatures and geolocation appear in the final report without extra admin.

- Faster audits and inspections: Evidence is captured instantly. There’s nothing to chase and nothing missing.

- Higher quality decisions: You can rely on accurate, granular execution data instead of incomplete reports.

- AI readiness: AI projects only succeed if the data feeding them reflects reality. Digital execution builds this foundation.

The Execution Layer and AI: Why One Cannot Work Without the Other

Many organisations want predictive maintenance, smarter scheduling, or AI-driven optimisation.

But AI cannot interpret paper forms, PDFs or inconsistent data.

What it needs is structured execution data — timestamps, decisions, operator actions, pass/fail events, captured evidence.

Without this, AI models remain theoretical.

Digital execution produces exactly that data, directly from work being carried out, without needing teams to change how they work.

This is how WorkfloPlus helps organisations become truly AI-ready.

FREE Resource: Discover why the Execution Layer is the missing link for AI-ready operations.

Beyond ERP, MRP & MES: Closing the Gap Between Planning and Reality to Enable AI-Ready Operations

Examples of the Execution Layer in Action

Manufacturing

Operators follow digital steps for quality checks, ensuring processes are identical across shifts and sites.Aviation MRO

Pre-flight checks and repairs become fully traceable with recorded evidence for every action.

Utilities

Field engineers capture GPS-stamped evidence instantly, eliminating reporting delays.

Rail

Safety checks, maintenance and inspections produce perfect audit trails automatically.

Construction

Digital guidance ensures assessments are completed to standard with instant evidence.

How WorkfloPlus Integrates With Your Existing Systems

WorkfloPlus enhances, rather than replaces, your existing digital ecosystem.

It integrates with platforms such as:

So the Execution Layer finally talks to your planning systems.