In oil and gas, every task counts. Whether you’re managing offshore rigs, refineries, or pipelines, you need your teams to work safely, stay compliant, and keep production running without interruption.

That’s where WorkfloPlus comes in.

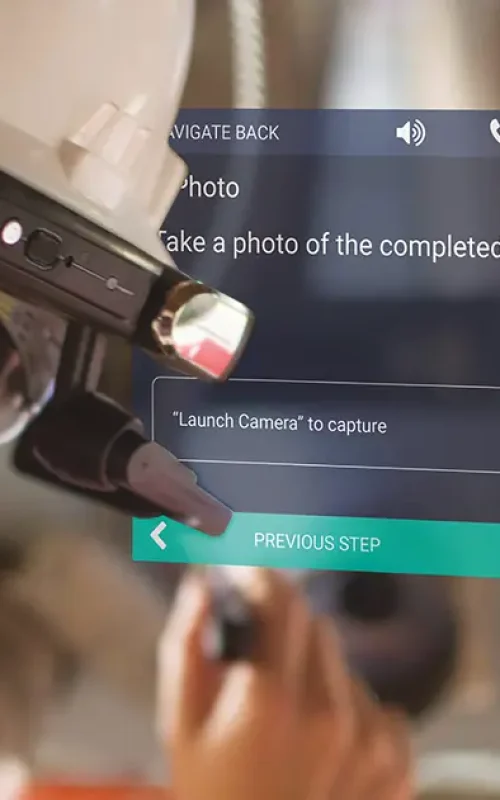

It replaces outdated paper checklists with digital SOPs (standard operating procedures) that your teams can follow step by step — on mobile or hands-free devices like the RealWear Navigator Z1. The result? Faster, safer, and more consistent operations with complete visibility across every site.

In oil and gas, every second counts. Whether you’re managing offshore rigs, refineries, or pipeline networks, your teams work in some of the most demanding environments in the world. When safety, compliance, and efficiency all depend on precision, there’s no room for guesswork.

That’s where WorkfloPlus helps you stay ahead. It replaces slow, paper-based systems with Digital SOPs (Standard Operating Procedures) — clear, step-by-step guidance your teams can follow anywhere, even in hazardous environments. The result? Safer operations, consistent performance, and full traceability across every task.

You get complete visibility of what’s happening on-site — from maintenance checks to inspection results — while your teams work confidently and efficiently using intrinsically safe, hands-free devices like the RealWear Navigator Z1.

WorkfloPlus connects your people, processes, and assets. It integrates with your existing CMMS and asset management systems, providing real-time insights into equipment health, maintenance needs, and operational performance. With instant remote support for offshore teams and automatic audit trails, you can reduce downtime, strengthen compliance, and focus on driving productivity.

Proven across the energy sector, WorkfloPlus helps you deliver measurable results — safely, efficiently, and consistently.

Outdated paper processes slow teams down and increase risk. Digital SOPs from WorkfloPlus guide your engineers through every step of the job, ensuring consistency, accuracy, and safety.

Whether your teams are onshore or offshore, you can standardise the way work gets done, reduce rework, and improve reliability across every site.

When something goes wrong, your teams shouldn’t have to wait for help. With WorkfloPlus, engineers in the field can connect instantly with remote experts through live video, photos, or voice notes.

Problems are solved faster, downtime is reduced, and costly site visits are avoided. You gain real-time visibility while teams stay productive, safe, and confident in every task.

WorkfloPlus works seamlessly with RealWear Navigator Z1, giving engineers the freedom to follow digital SOPs hands-free. They can view instructions, capture data, and record evidence without ever needing to stop what they’re doing.

This improves safety and efficiency while giving you accurate, real-time updates from the field — connecting your workforce like never before.

By integrating with CMMS, IoT sensors, and digital twin platforms, WorkfloPlus provides actionable insights into equipment performance and health.

Predictive maintenance becomes part of your routine — not a reaction to failure. You’ll reduce unplanned downtime, extend asset life, and optimise performance across every site.

In an industry where compliance is non-negotiable, WorkfloPlus makes it simple. Every task, inspection, and maintenance activity is automatically logged, creating a full digital audit trail that aligns with HSE, ISO, and environmental standards.

You can demonstrate compliance instantly, eliminate audit stress, and make regulatory adherence a natural part of your daily operations.

Every process completed in WorkfloPlus generates structured, high-quality data that feeds into AI, analytics, and predictive systems.

That means you’re not just improving how work gets done today — you’re laying the foundation for the digital transformation and energy transition that define the future of your industry.

WorkfloPlus helps onboard new engineers faster and keeps existing teams up to date with the latest procedures. Digital SOPs make complex tasks simple, reducing reliance on experience alone and ensuring consistent, safe performance.

By capturing and standardising operational knowledge, you preserve critical expertise and accelerate learning — giving your workforce the confidence to perform in even the toughest conditions.

Intoware’s customer success model ensures your project achieves it’s goals, and provides ROI as quickly as possible.

On our Discovery call, we’ll find out about you and your existing processes to learn exactly what you’re looking for.

Configure your workflows. Customise templates with our toolkit or build processes from scratch.

Integrate your digital workflows with existing devices. We’re on hand to help with training, support and integration.

Stop worrying about visits from regulators and auditors. WorkfloPlus automatically builds rock-solid evidence trails for Health & Safety, ISO standards, and industry regulations. When inspectors ask "Can you demonstrate this was done properly?" At the click of a button you can!

Convert your paper-based SOPs, machine setups, and maintenance procedures into smart digital work instructions that are always current, always accessible. When procedures change, just make the update once and instantly roll-it out across all devices. End the hassle of outdated printouts and version confusion.

Transform routine inspections into early warning systems. Identify patterns in equipment deterioration, catch recurring problems, and demonstrate exactly when issues first appeared, and why. Turn your inspections into problem-prevention tasks that save your business money.

Don't lose decades of experience when workers leave. WorkfloPlus captures how your best performers actually do the job, then turns that knowledge into training that new starters can follow. See exactly where people struggle and build a library of proven methods to pass on to the next generation

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.