Connected Frontline Operations

Bringing People, Processes and Data Together

Most organisations are well connected at the top.

Plans are defined. Systems are integrated. Dashboards are built.

But on the frontline, work often still happens in isolation.

Instructions live in PDFs.

Processes are in peoples heads.

Checks are completed on paper.

Photos sit on phones.

Reports are written up later.

For service engineers, field technicans and frontline workers, this disconnect is felt every day. And by the time information reaches decision-makers, the moment has usually passed.

Connected frontline operations close this execution layer gap. Not by adding more paperwork, but by connecting field teams to the guidance, data and context they need while they actually complete the work.

What “Connected” Really Means on the Frontline

Being connected isn’t about issuing another device or tool.

It’s about ensuring that the work carried out on site, on the factory floor or in the field feeds directly into the wider operation.

In a connected frontline operation, service engineers and field technicians don’t work in isolation from the rest of the business. Their actions, checks and decisions become visible, traceable and useful in real time.

The frontline stops being a blind spot and becomes a reliable source of operational insight.

Why Frontline Disconnection Holds You Back

When frontline teams aren’t connected, problems don’t appear immediately.

They build quietly over time.

Managers lack visibility into how work is actually being carried out.

Training gaps go unnoticed.

Variation becomes normalised.

Compliance relies on trust rather than evidence.

Continuous improvement initiatives stall because information arrives too late.

This isn’t a people problem.

It’s a connection problem.

Maintenance engineers, service engineers and field technicians are often doing the right work — but the organisation lacks the structure to see it, support it or learn from it consistently.

Free Download: The Connected Workforce eBook

Explore the benefits of connected working for both the frontline workers, and business operations.

Connecting Work as It Happens

Connected frontline operations bring guidance, confirmation and evidence capture into the same moment.

Instead of relying on memory or paperwork, frontline teams follow clear steps on screen.

Instead of reporting later, evidence is captured as the task is completed.

Instead of chasing updates, supervisors and managers see progress as it happens.

For field engineers and service engineers working remotely, this means capturing inspections, updates and compliance evidence without returning to site or the office.

Connection becomes practical, not theoretical.

From Isolated Tasks to Shared Visibility

When frontline work is connected, small actions no longer disappear.

Every confirmation.

Every photo.

Every reading.

Every decision.

This level of visibility changes how organisations operate.

Leaders can see where processes vary.

Supervisors can intervene earlier.

Training becomes targeted rather than generic.

Compliance becomes provable rather than assumed.

Frontline activity finally connects to operational reality.

Supporting the People Doing the Work

Connected operations are not about monitoring people more closely.

They are about supporting people better.

Service engineers gain clarity on what’s expected.

Field technicians feel more confident completing tasks correctly.

Maintenance engineers spend less time interpreting instructions and more time doing the work.

New starters ramp up faster.

Experienced staff spend less time explaining and more time improving.

Knowledge is captured before it’s lost.

When systems support people properly, adoption follows naturally.

Connected Operations Across Different Environments

The need for connection looks different depending on where work takes place.

On the factory floor, connection helps standardise tasks across shifts and reduce variation.

In the field, it allows engineers and technicians to stay aligned without constant supervision.

In regulated or safety-critical environments, it ensures checks are completed consistently and evidence is captured correctly.

The common thread is clarity at the point of work.

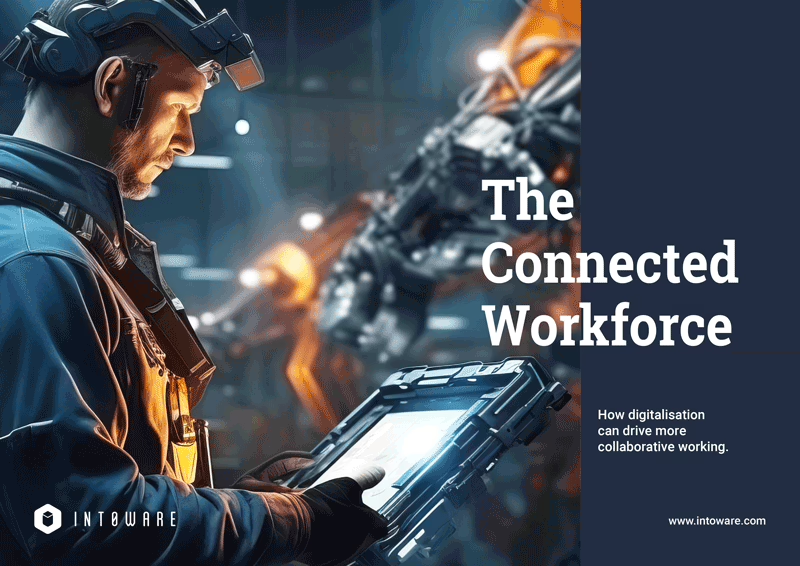

Hands-Free Connection Where Safety Comes First

Some frontline roles demand full focus and both hands free.

Working at height, wearing gloves or operating around live equipment leaves little room for manual data entry.

Hands-free access to guidance and evidence capture allows service engineers and field technicians to complete required checks without compromising safety.

Using voice-controlled smart glasses, confirmations and photos are captured as work happens, while protective equipment remains in place.

This is especially valuable in utilities, rail, aviation MRO, construction and energy environments – where safety and compliance cannot be separated.

Turning Frontline Activity into Operational Insight

When frontline work is connected, it produces more than completed tasks.

It produces structured, reliable data.

Over time, organisations gain visibility into:

- where delays occur

- which steps create friction

- how performance differs between teams or sites

- where additional training is needed

- which processes need attention

This insight supports continuous improvement based on reality, not assumption.

Whitepaper Download: Unlock the Value in Data

Explore how to make the most of industrial data insights for future growth.

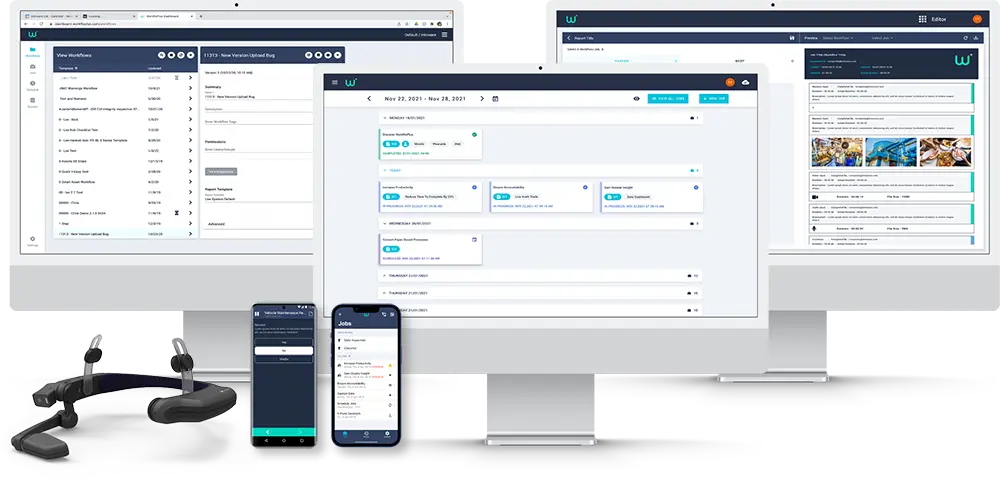

Connection Without Lock-In

Connected frontline operations work best when they fit naturally into existing environments.

WorkfloPlus is device-agnostic.

Service engineers and field technicians can work on phones, tablets or smart glasses — switching devices depending on the task, location or safety requirements.

Connection stays consistent, even as environments change.

Examples of the connected working in Action

Manufacturing

Operators follow digital steps for quality checks, ensuring processes are identical across shifts and sites.Aviation MRO

Pre-flight checks and repairs become fully traceable with recorded evidence for every action.

Utilities

Field engineers capture GPS-stamped evidence instantly, eliminating reporting delays.

Rail

Safety checks, maintenance and inspections produce perfect audit trails automatically.

Construction

Digital guidance ensures assessments are completed to standard with instant evidence.

See how connecting frontline work improves visibility, consistency and confidence.

Request a short walkthrough tailored to needs or your service engineers, field technicians and operational teams.