Digital SOPs & Digital Work Instructions

A Practical Guide for Operation Optimisation

If you still rely on paperwork, PDFs, or tribal knowledge to get critical tasks done, you’re not alone.

Most companies want consistency, traceability and fewer errors, but the reality on the ground doesn’t make this easy.

Digital SOPs and digital work instructions provide clear, step-by-step guidance, while automatically capturing the evidence you need for audits, training, compliance and continuous improvement.

And the best part? You don’t need to overhaul your entire operation to get started.

This guide breaks down what digital work instructions are, why they matter, and how they can transform the way work is carried out across your organisation.

What Are Digital SOPs and Digital Work Instructions?

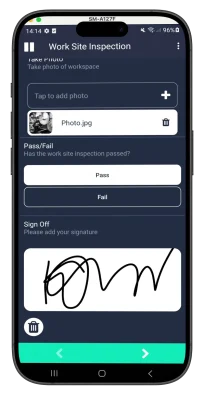

Digital SOPs and digital work instructions turn your processes into simple, clear, on-screen guidance that teams follow as they complete a task.

Instead of flipping through a binder, searching for the right PDF, or relying on memory, workers see the exact steps they need. As well as any checks, photos, data points or confirmations required.

They provide:

- Clear, structured guidance

- Real-time evidence capture

- Consistent execution

- Automated reporting

- Instant visibility

In other words, they close the gap between how work should happen and how it actually happens.

Why Paper SOPs Struggle in Today’s Operations

Paper isn’t the issue. It’s what paper prevents.

Most paper-based or static SOP formats create problems long before work even starts:

- No way to ensure people follow the latest version

- No visibility into how tasks are actually completed

- No automatic evidence capture when someone needs to prove compliance

- No connection between what should happen and what really happened

- No way to learn from the thousands of small decisions made every day

Even the most experienced team members end up relying on memory, habit or guesswork, because the information they need lives everywhere except where the work takes place.

Digital SOPs fix this by bringing the process directly to the point of use, guiding the task in real time and capturing evidence as part of the job itself.

Free Download: Digital SOPs eBook

Learn how digital standard operating procedures increase productivity, reduce wastage and ensure compliance.

How Digital SOPs Transform Daily Work

The biggest change isn’t the technology. It’s the clarity.

When every step is shown on-screen, when checks can’t be skipped, when photos and confirmations are built into the task, teams naturally become more:

- consistent

- confident

- compliant

People spend less time thinking “What’s next?”

And more time thinking “This is how the job should be done.”

Managers stop chasing information.

Auditors stop questioning evidence.

New starters start being productive faster.

Instead of trying to remember the process, they can simply follow it.

Digital SOPs act as a coach, not a document.

Training and Upskilling Become Faster and More Reliable

A new starter no longer needs to shadow someone for days.

An experienced operator no longer has to “just know” how the job should be done.

And teams no longer lose knowledge every time a skilled worker moves on.

Each task becomes a real-time learning experience, reducing the pressure on people and accelerating confidence.

It’s the simplest way to preserve tribal knowledge. By turning it into something everyone can use.

Resource Download: Industry 5.0 — Putting People at the Heart of Operations

Digital SOPs don’t replace people. They support them.

This eBook explores how modern organisations are using digital tools to empower workers, preserve knowledge and build AI-ready operations.

Instant Evidence Without Extra Work

One of the biggest challenges with audits, investigations or incident reviews is proving what happened.

Paper-based systems rely on good handwriting, good memory and good luck.

Digital SOPs change that.

Every confirmation, every photo, every reading and every timestamp becomes part of the record automatically.

There’s no extra admin, no backlogs, no missing signatures and no last-minute panic before an audit.

Evidence becomes a natural by-product of the work — not an admin.

A Single Source of Truth for Every Site and Every Shift

When SOPs live in binders or folders, variation creeps in.

Not because people are careless, but because they can only work with what’s in front of them.

Digitalising your instructions ensures:

- Everyone uses the same version

- Updates go live instantly

- Changes are rolled out with no disruption

- Standards remain predictable across teams, shifts and locations

It brings harmony to operations that would otherwise drift apart.

What Digital SOPs Unlock for Your Organisation

Digital SOPs don’t only guide tasks. They generate the high-quality execution data you’ve been missing.

This includes:

- Which steps take the longest

- Where people get stuck

- Which checks fail most often

- Which processes generate the most variation

- Where training gaps appear

- How performance differs between teams or sites

Those insights help you improve processes with confidence, because finally, you can see what’s actually happening.

This is the foundation of AI-ready operations: real, step-level, human execution data.

FREE Resource: Discover why the Execution Layer is the missing link for AI-ready operations.

Beyond ERP, MRP & MES: Closing the Gap Between Planning and Reality to Enable AI-Ready Operations

Where Digital SOPs Deliver the Most Impact

Manufacturing, aviation MRO, rail, utilities, construction and field service teams use digital SOPs to solve some of their biggest challenges:

- Reducing variation in safety-critical tasks

- Delivering consistent quality checks

- Accelerating training and onboarding

- Improving audit readiness

- Capturing evidence in hazardous or remote environments

- Replacing paperwork with live, accurate data

Digital work instructions scale because they meet teams where they are. Whether that’s on the factory floor, on-site, or out in the field.

Examples of Digital SOPs in Action

Manufacturing

Operators follow digital steps for quality checks, ensuring processes are identical across shifts and sites.Aviation MRO

Pre-flight checks and repairs become fully traceable with recorded evidence for every action.

Utilities

Field engineers capture GPS-stamped evidence instantly, eliminating reporting delays.

Rail

Safety checks, maintenance and inspections produce perfect audit trails automatically.

Construction

Digital guidance ensures assessments are completed to standard with instant evidence.