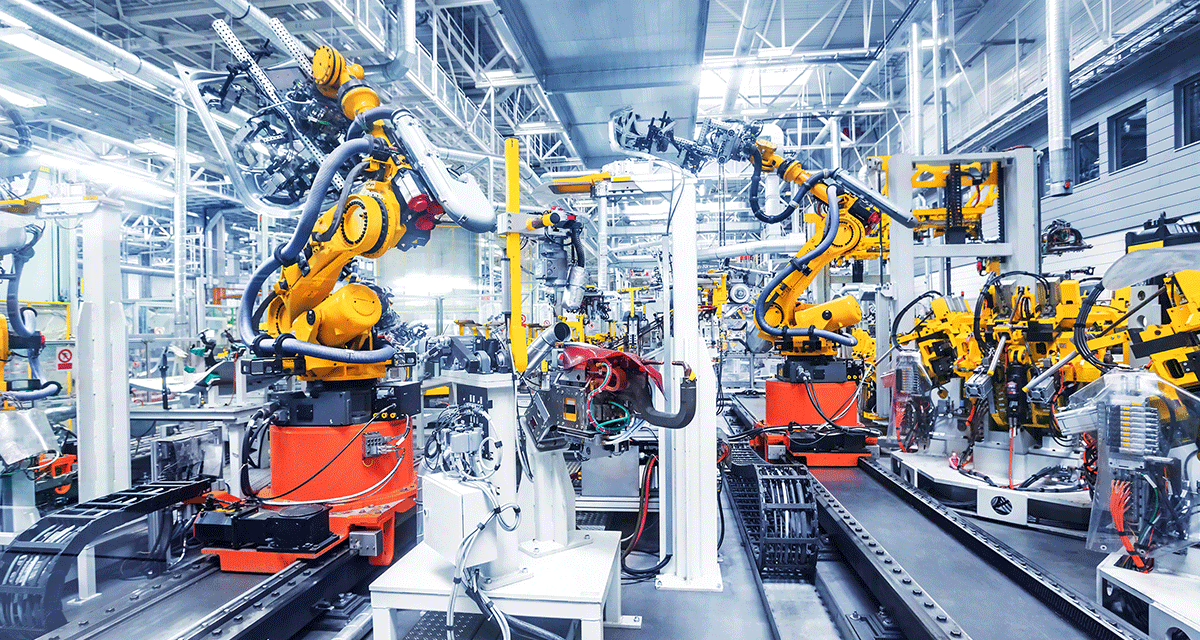

A smart factory uses advanced digital technologies to connect systems, people, and machines in real time. It focuses on automation, data-driven decision-making, and continuous optimisation. They rely on technologies such as IoT sensors, AI, cloud computing, robotics, and real-time data capture.

The goal of a smart factory is to create seamless production flow with minimal waste and maximum insight. Machines and systems communicate with each other automatically, while frontline teams use digital tools to perform tasks more efficiently.

They rely on accurate, continuous data from both machine activity and human actions. This combination enables end-to-end optimisation.

How this applies to WorkfloPlus

WorkfloPlus plays a key role in smart factory environments by digitising frontline execution. It guides workers through tasks and captures operational evidence in real time. This connects human activity to the same data ecosystem as machine performance.

With WorkfloPlus , organisations achieve higher consistency, improved compliance, and better insight into production processes – all essential components of a smart factory strategy.