Digital Inspections

A Practical Guide to Safer, Smarter Operations

Inspections are one of the most important parts of running a safe, efficient and well-managed operation. Whether it’s a quick equipment check, a safety walk, a quality control step or a full maintenance procedure, inspections exist for one reason: to make sure work is carried out correctly and safely.

But this is also where many organisations struggle.

When inspections rely on paper, PDFs or memory, information gets delayed, evidence goes missing and visibility disappears as soon as the inspector leaves the site.

Digital inspections change that entirely.

They bring clarity to every check, structure to every step and evidence to every decision – while removing admin and paperwork.

This guide explains what digital inspections are, why they matter and how they can transform safety, quality and performance across your organisation.

The Challenge With Traditional Inspections

Paper isn’t the issue.

It’s the gaps paper creates.

Even well-trained teams face the same problems:

- reports that are delayed or incomplete

- inconsistent interpretation of checks

- missing photos or signatures

- uncertainty about the latest version

- limited visibility for supervisors

- difficulty spotting recurring issues

Inspectors often have to do the work twice — first on paper, then later when manually entering information into a system.

Managers end up making decisions based on outdated or incomplete reports.

And small issues can turn into larger problems simply because nobody could see them early enough.

Digital inspections remove these blind spots and make every check reliable the moment it’s completed.

Free Download: Digitalisation: The Key to Compliance

This guide explains how to manage risk and regulatory compliance through digital inspections.

What Digital Inspections Deliver in Practice

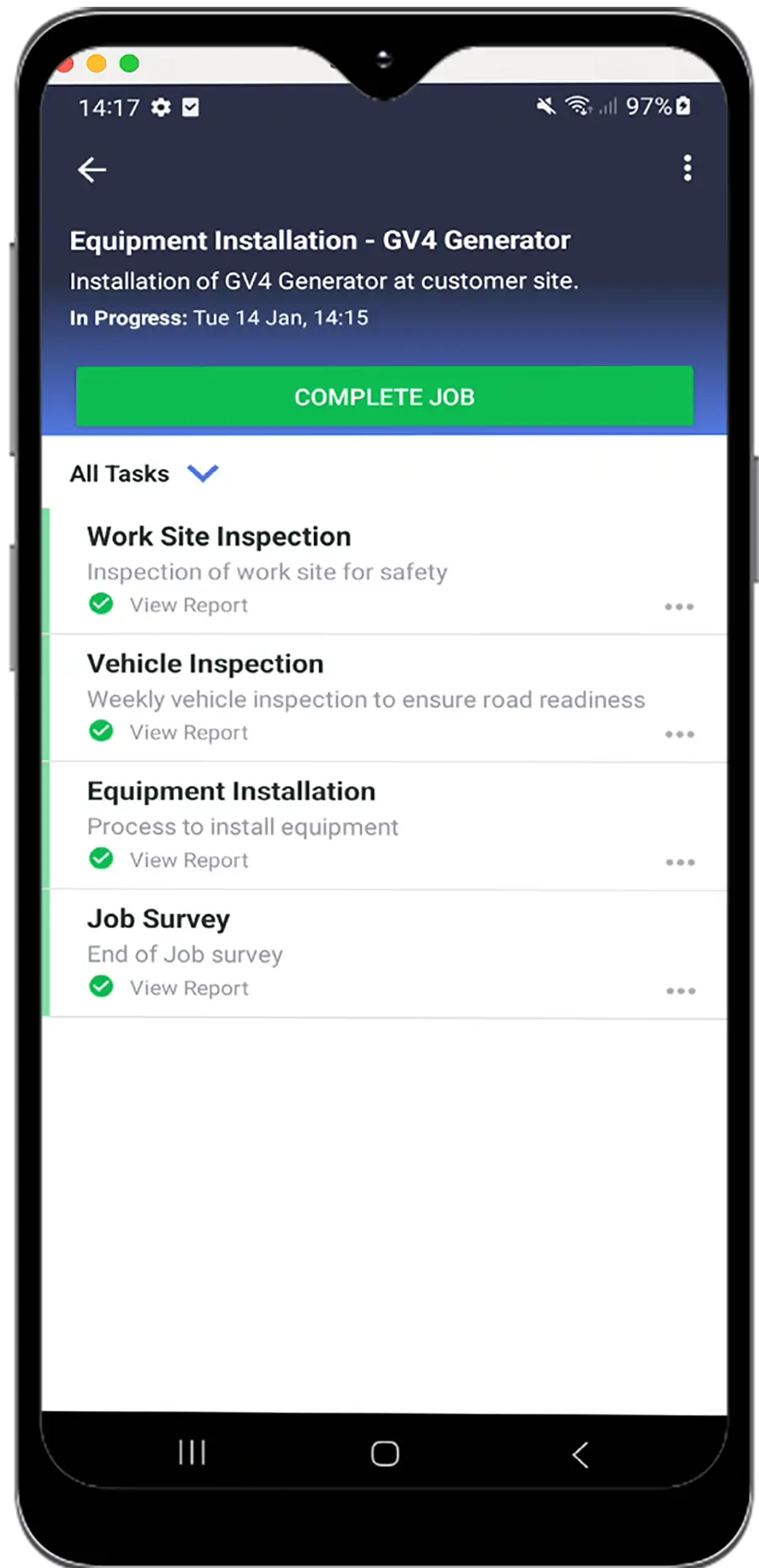

A digital inspection brings structure and guidance to the exact moment the work happens.

Instead of trying to remember the process or fill in a form at the end, inspectors follow clear steps on screen and capture evidence in real time.

Photos become proof.

Readings become data.

Checks become consistent.

Reporting becomes instant.

And teams no longer have to repeat work.

Digital inspections turn the inspection itself into a source of truth. A source of truth you can trust immediately.

What Inspections Can Be Improved with Digitalisation?

Every organisation performs inspections, but the purpose behind each one varies.

WorkfloPlus supports them all because the principles stay the same: clarity, consistency and traceability.

Equipment Inspections

Daily equipment checks confirm that tools, machinery and assets are safe to use.

Digital inspections let teams capture readings, photos and observations instantly, preventing minor issues from becoming major downtime events.

Health & Safety Inspections

Safety inspections play a crucial role in identifying risks, confirming site readiness and ensuring procedures are followed correctly.

Digital inspections make every finding available immediately, improving accountability and reducing the chance of incidents.

Maintenance Inspections

Maintenance teams need accurate information to plan work effectively.

Digital inspections ensure every reading, measurement and result is captured cleanly, giving engineering teams the detail they need to improve asset reliability.

Quality Inspections

Quality checks often require precise evidence — measurements, pass/fail checks, photos or serial numbers.

Digital inspections make this easy and consistent, while automatically generating a complete, audit-ready trail.

Compliance & Regulatory Inspections

Whether it’s ISO standards, safety regulations or sector-specific requirements, compliance depends on reliable evidence.

Digital inspections create that evidence automatically.

Confirmations, timestamps and records are captured during the inspection itself, making audits far faster and far less stressful.

Field Inspections

Teams working across large areas — rail, utilities, construction, highways, oil & gas — need inspections that work anywhere.

Digital inspections remove the need for paper, ensure data isn’t lost and let supervisors see results instantly, even when teams are remote.

Hands-Free Inspections

Some inspection environments make it difficult, or even unsafe, to hold a device.

Working at height, wearing gloves, climbing structures or operating in hazardous areas all limit what inspectors can safely carry.

Hands-free digital inspections solve this.

Using voice-controlled smart glasses, inspectors can follow each step, take photos and record evidence without stopping their work or removing protective equipment.

It keeps both hands free, reduces risk and ensures every inspection is completed accurately, even in challenging environments.

Free Download: Digital SOPs eBook

Learn how digital standard operating procedures increase productivity, reduce wastage and ensure compliance.

Why Digital Inspections Improve Safety and Reduce Risk

Safety improves when people complete the right steps in the right order, and when supervisors can see the moment something needs attention.

Digital inspections support this by:

- guiding inspectors clearly in real time

- surfacing issues immediately

- providing reliable evidence

- reducing manual errors

- ensuring nothing is missed

It isn’t about replacing expertise.

It’s about giving people the support and clarity they need to do the job confidently, consistently and safely.

Turning Inspections into Insight

An inspection is more than a checklist. It’s the moment where you learn something.

But when inspections live on paper or spreadsheets, those lessons disappear.

Digital inspections make learning continuous.

Companies gain visibility into:

- recurring issues

- delays and bottlenecks

- where checks are failing

- how inspections vary between sites

- where extra training might be needed

- which assets need attention sooner

This is the foundation of continuous improvement.

Based on real evidence, not assumptions.

Resource Download: How to Unlock the Value in Data Whitepaper

This eBook explores how to make the most of industrial data insights for future growth.

Real-World Examples of Digital Inspections in Action

Manufacturing

Operators follow digital steps for quality checks, ensuring processes are identical across shifts and sites.Aviation MRO

Pre-flight checks and repairs become fully traceable with recorded evidence for every action.

Utilities

Field engineers capture GPS-stamped evidence instantly, eliminating reporting delays.

Rail

Safety checks, maintenance and inspections produce perfect audit trails automatically.

Construction

Digital guidance ensures assessments are completed to standard with instant evidence.