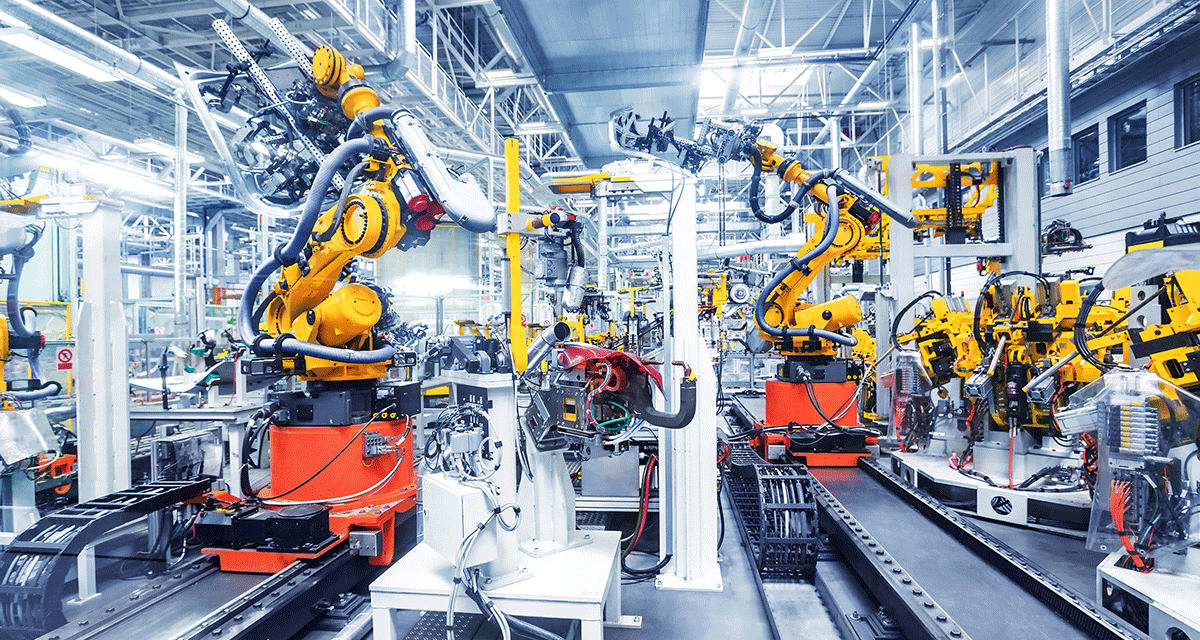

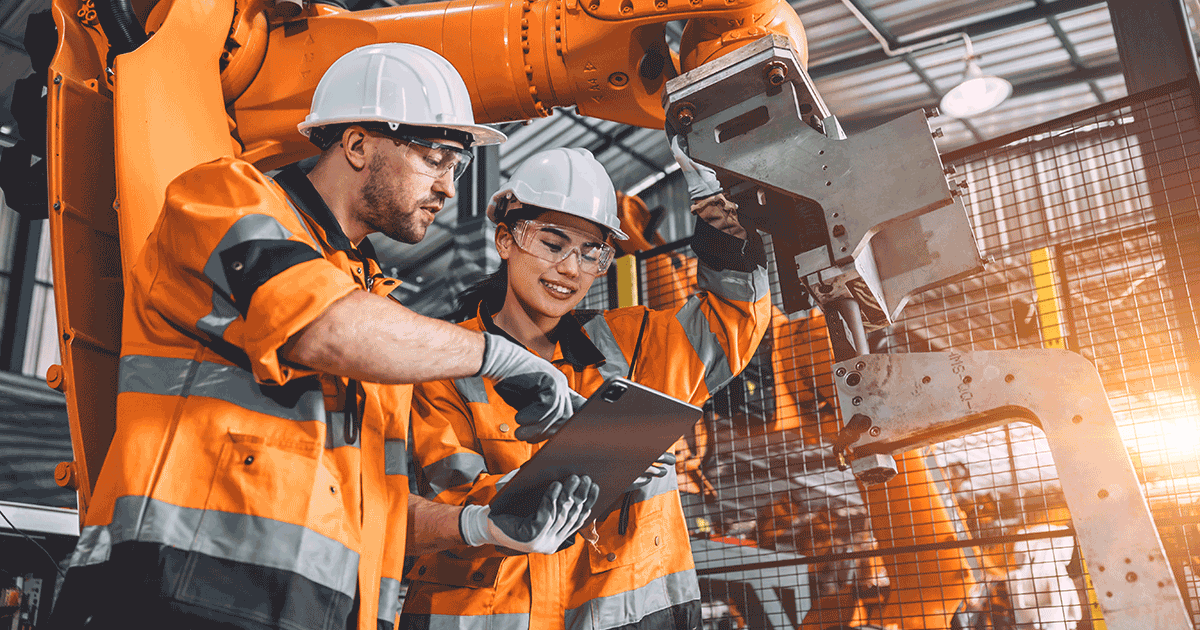

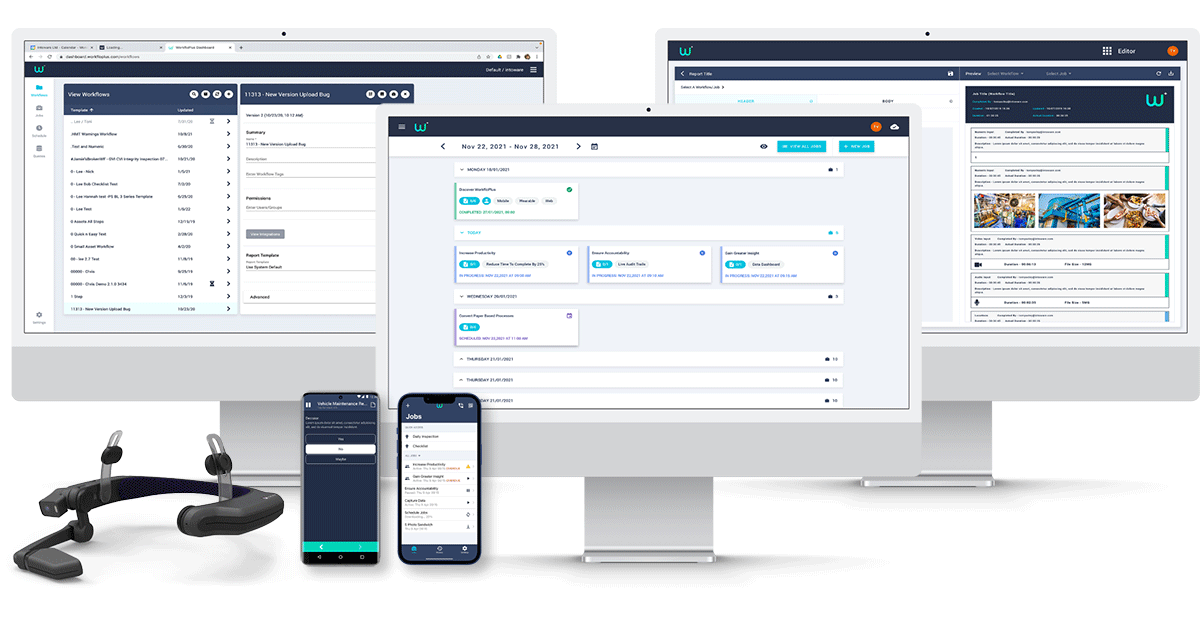

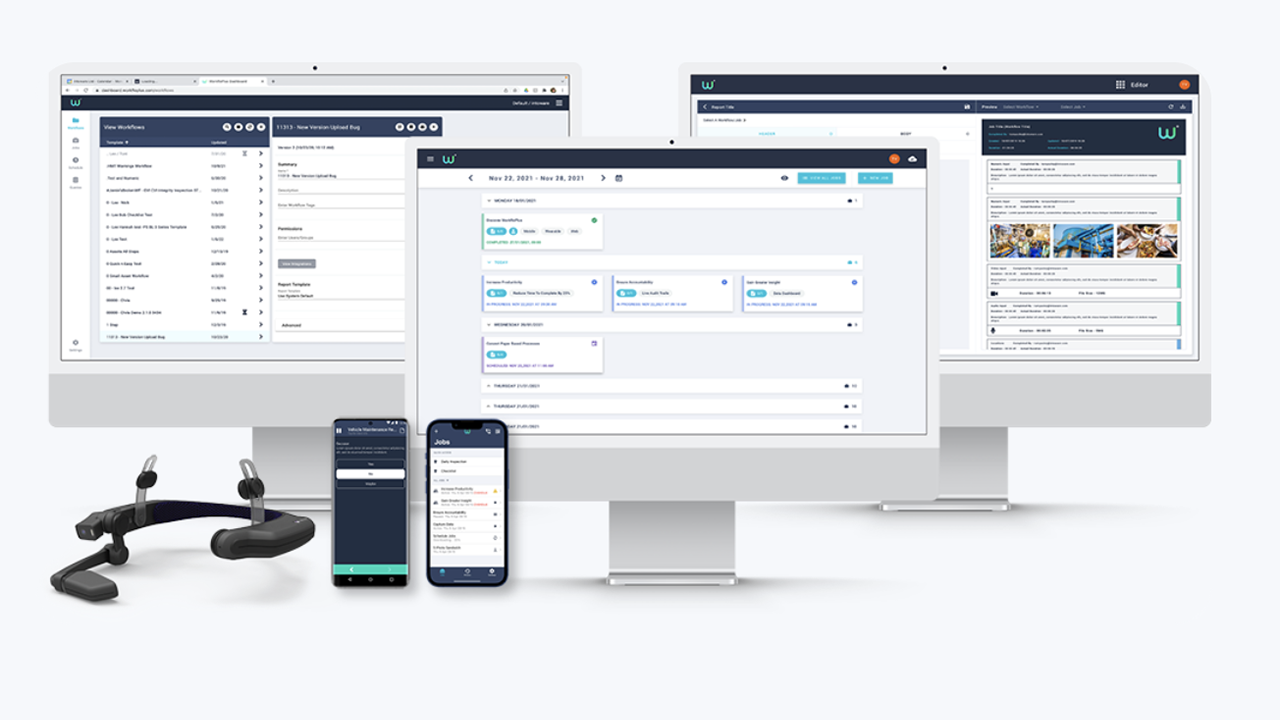

A division of one of the world’s largest and respected automotive suppliers is seeing the benefits of the WorkfloPlus software in busy and critical areas of their plant operations. On a typical day thousands of bumpers, tailgates and other components are sprayed, assembled and processed and mistakes in the process can result in significant cost. Using WorkfloPlus hasn’t only removed the need for paper-based checks but provided much needed visibility and assurance that the correct set up processes are followed with clear audit trails for the team.

"Using paper-based checks was something very ingrained into the processes here, and even highly experienced staff can sometimes miss something, so WorkfloPlus seemed a great starting point for our desire to change and modernise the way we work."

WorkfloPlus has already shown its value thanks to the ability to very quickly trace back through the data and find the source of the problem on the production line.

“In one case, we were able to clearly show that a quality issue was due to a specific batch of paint and take immediate action to take that batch offline, saving tens of thousands of pounds in re-work down the line.”

With pressures to deliver a high volume of high-quality products on a ‘just-in time’ basis it is critical that any paint set up and spraying errors are avoided. However, despite the high-tech production line, many essential checks were still being done with pen and paper. Mistakes can mean re-spraying several hundreds of car bumpers which can be costly to the business.

With so many components passing through the facility every day - at peak, they could be painting several thousand parts -WorkfloPlus helps the team be proactive rather than reactive. Any parts which don’t pass quality control need to be identified, and the part sent to be refinished. If the issue lies with the batch of paint itself, then that could mean hundreds or even thousands of parts could be affected.

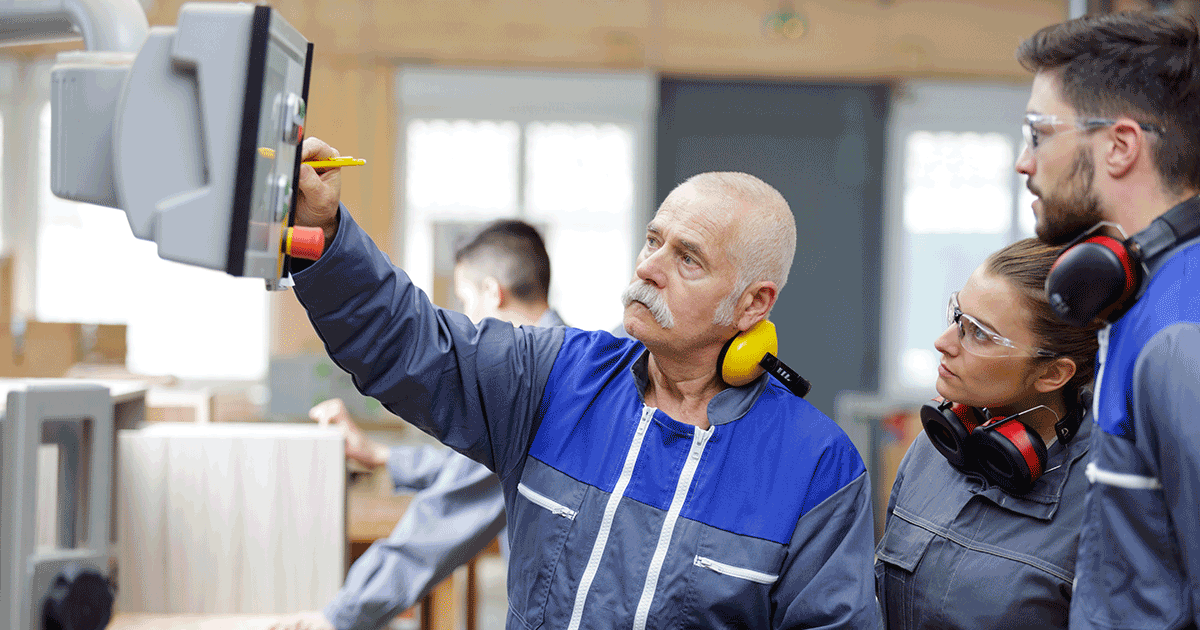

WorkfloPlus means they can now achieve up to 92% accuracy whilst quickly identifying any potential issues before they happen. Added to this is the benefit of being able to use these new digital processes to help train and quickly upskill new staff, meaning they can share several years’ worth of knowledge and experience bringing new team members up to speed much faster than previously experienced. With the reporting modules taking every bit of data recorded, management can see live, real-time views of their areas performance and staff can quickly contribute to improving and adapting processes.

"The partnership with Intoware & the adoption of WorkfloPlus is saving us a huge amount of time but also helping us with quality, performance & staff training. It’s an investment that’s delivering value today & for the future."

.jpg)

.gif)